Investing in a Battery Energy Storage System (BESS) is a smart move for many commercial and industrial (C&I) businesses today. These systems help you save money on electricity bills and keep your power on when the grid goes down. But a BESS isn’t just a big battery. It has several key parts that work together. One of the most important is called the PCS.

What exactly is a PCS? Why does your C&I BESS absolutely need it? This article will break it down for you. We’ll cover what a PCS does, the different kinds you might find, what benefits it brings, and the most important things to look for when choosing a BESS for your business. Let’s get started.

Kamada Power 215 kwh 200 kwh BESS Battery

What is a PCS in C&I BESS?

Think of your BESS battery like a big tank holding energy. This energy is stored as DC power. Most of the electricity your building uses, and the power from the grid, is AC power. DC and AC are different. You can’t directly use DC power from the battery to run your AC lights or machinery. You also can’t directly put AC power from the grid into a DC battery to charge it.

This is where the PCS comes in.

What is Power Conversion System (PCS)

The Power Conversion System, or PCS, is a piece of equipment that acts like a smart translator for electricity. Its main job is to change electric power from one form to another.

- When you need to use the energy stored in the BESS battery, the PCS takes the DC power and converts it into AC power. This is called discharging.

- When you need to put energy into the BESS battery from the grid or your solar panels, the PCS takes the AC power and converts it into DC power. This is called charging.

So, the PCS allows power to flow both ways between the DC battery and the AC world of your building and the grid. It’s a bidirectional converter.

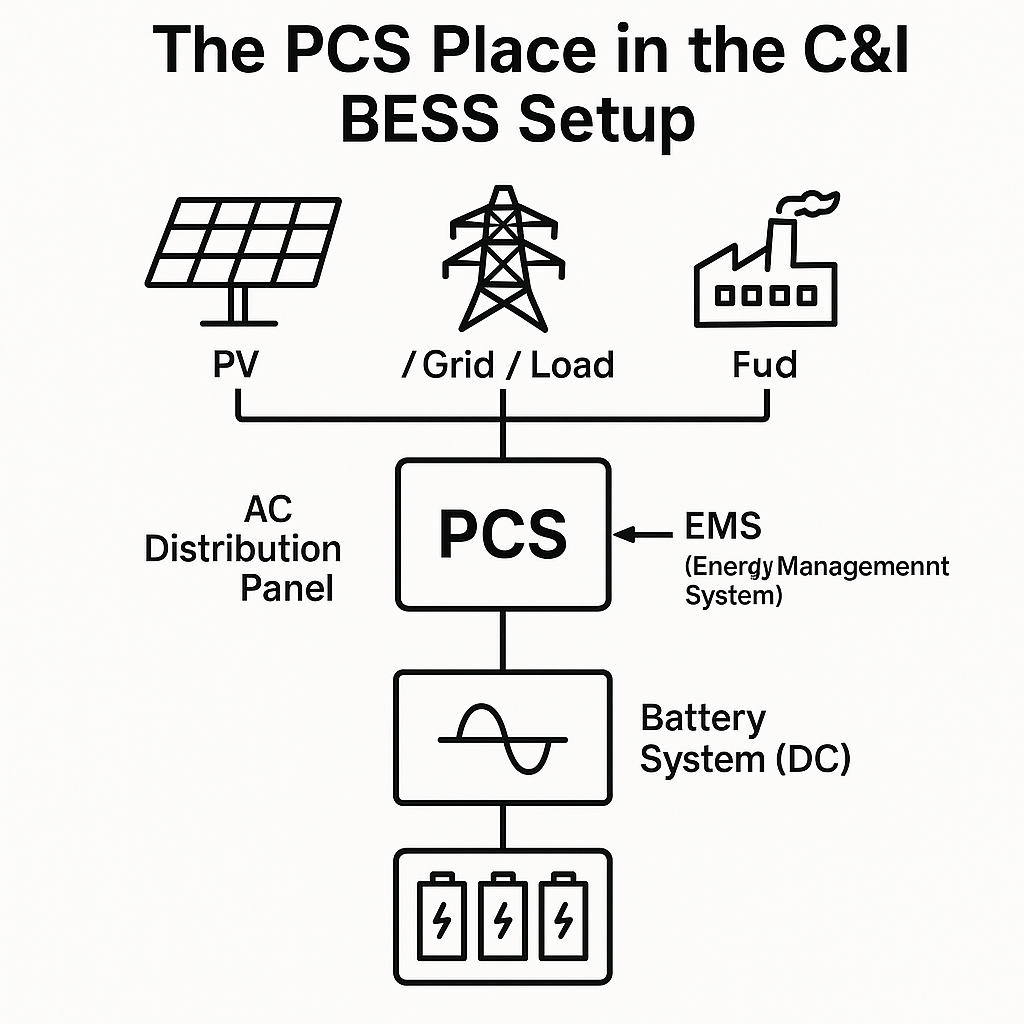

The PCS Place in the C&I BESS Setup

Diagram Description:

- Top (AC Side): Connects to the grid, photovoltaic (PV) system, or commercial and industrial loads.

- Middle (PCS): The core power conversion component enabling bidirectional AC↔DC energy flow.

- Bottom (DC Side): Connects to lithium battery modules, BMS, battery cabinets, and other energy storage units.

- Side (EMS): The source of control and dispatch commands, responsible for regulating operation modes and charge/discharge strategies.

Without the PCS, the energy in your BESS battery would just sit there, locked away. The PCS makes that stored energy useful for your business.

Why the PCS is Essential for Optimizing C&I BESS Value

The PCS does more than just change power types. It’s key to getting real value out of your BESS investment.

Enabling Critical BESS Operational Capabilities

The PCS is like the conductor of an orchestra for your BESS. It doesn’t just convert; it controls the power flow precisely.

- It controls how fast and how much power goes into or out of the battery. This control is vital for following the plan set by the EMS – whether that’s charging slowly overnight or sending a big burst of power to cut peak demand.

- It makes sure the power coming out is clean and stable. It regulates the voltage and frequency to match what your building and the grid need. This keeps your equipment safe and happy.

These control abilities unlock the ways you can use your BESS.

How a Capable PCS Drives Business Benefits: Cost Savings and Resilience

The PCS is directly linked to the money you save and the reliability you gain.

- Cutting Electricity Bills: A smart PCS works with the EMS to perform actions like:

- Huipun säästäminen: Sending power from the BESS during your facility’s highest usage times to lower your demand charges (those fees based on your highest power spike). A fast, responsive PCS is needed here.

- Time-of-Use Arbitrage: Charging the BESS when electricity prices are low (like at night) and discharging it when prices are high (like during the day). The PCS handles this scheduled power movement.

- Keeping the Lights On: If the grid goes down, a PCS with “islanding” capability can quickly disconnect from the grid and start powering your building directly from the BESS. This is essential backup power. The PCS manages this switch and keeps your facility running smoothly on battery power.

A high-quality PCS is a workhorse that makes these valuable operations possible.

PCS Options for Your C&I BESS: Understanding the Different Types

Not all PCS units are built the same. Different types are better for different BESS sizes and needs. Knowing the options helps you choose wisely.

Centralized vs. Modular PCS: Which Design Fits Your BESS Project?

This is about how the PCS power is packaged:

- Centralized PCS: One large PCS unit handles the entire battery bank.

- Plussaa: Can be simpler to install, potentially lower upfront cost for very large systems.

- Miinukset: If the single PCS fails, the entire BESS is down. Less flexibility for adding more battery later.

- Modular PCS: The total PCS power is split among several smaller units, sometimes connected to sections of the battery bank (like inverters for string solar systems).

- Plussaa: If one module fails, the others keep working, meaning your BESS still provides some power (better redundancy). Easier to scale up your BESS later by adding more battery and PCS modules. Can sometimes be more efficient at lower power levels.

- Miinukset: Can sometimes have a slightly higher upfront cost.

Think about how critical uptime is for you. Modular designs offer more backup protection within the BESS itself.

Air-Cooled vs. Liquid-Cooled PCS: What’s the Real-World Difference?

PCS units create heat when they convert power. They need cooling.

- Air-Cooled PCS: Uses fans to push air over components, removing heat.

- Plussaa: Simpler technology, often lower cost, easier maintenance.

- Miinukset: Can be bulkier, less efficient at cooling (especially in hot environments), performance might drop in very hot conditions, more sensitive to dusty air.

- Liquid-Cooled PCS: Uses a special liquid that flows through the PCS to absorb and move heat away.

- Plussaa: More efficient cooling, allows for smaller, more compact PCS units (higher power density), performs better in hot environments, less sensitive to air quality.

- Miinukset: More complex system, can have higher upfront cost, maintenance involves managing the cooling liquid.

For large, high-power BESS units, especially in warmer climates or tight spaces, liquid cooling is often chosen for its performance advantages. For smaller systems or less demanding conditions, air cooling works just fine.

Grid-Tied vs. Islanding PCS: Do You Need BESS for Backup Power?

This is a critical difference based on what you need your BESS to do during a power outage.

- Grid-Tied PCS: These on be connected to the live utility grid to work. If the grid power goes out, the PCS automatically shuts down for safety (to prevent sending power back onto a downed line). It cannot power your building alone.

- Use Case: Great for peak shaving, time-of-use savings vain while the grid is up.

- Islanding PCS: These can sense when the grid is down, safely disconnect from it, and then continue to operate, creating a small, independent grid (an “island”) to power critical loads in your building directly from the BESS.

- Use Case: Essential for backup power, ensuring your critical operations continue during blackouts. Adds complexity and cost compared to grid-tied only.

If keeping your business running during outages is a key goal, you on specify a BESS with an islanding-capable PCS.

Choosing the Right PCS for Your C&I BESS: What to Look For

Selecting the right BESS means selecting the right PCS within it. Don’t just focus on the battery size (kWh). Here’s what smart buyers consider:

Aligning PCS Specifications with Your BESS Goals

Your business goals should drive your PCS needs.

- Power Output (kW): How much power can the PCS deliver aikoinaan? If your goal is to cut a high peak demand spike, you need a PCS with a high kW rating that matches that spike. If it’s just long-duration backup for smaller loads, a lower kW might be okay.

- Energy Throughput (kWh): While this is more about the battery, ensure the PCS is rated to handle the energy cycling you expect over the BESS’s life.

Why PCS Efficiency (RTE) is Key to Maximizing Your BESS ROI

Efficiency means how much energy is lost during the conversion process. The Round Trip Efficiency (RTE) of the whole BESS is critical, and the PCS plays a big role in this.

High PCS Efficiency = Less Energy Wasted = More Usable Energy from Your BESS = Greater Cost Savings & Faster ROIEven a small difference in efficiency can mean significant money over the system’s lifespan. Ask for the PCS’s efficiency rating at different load levels (e.g., 25%, 50%, 100% power), as it changes.

Ensuring Seamless Compatibility within Your BESS Ecosystem

A BESS is a system. The PCS needs to talk perfectly with the battery’s BMS and the overall EMS.

- Battery Compatibility: The PCS must be designed to work with the specific battery chemistry and voltage range (e.g., LiFePO4, 48V, 400V).

- EMS Communication: The PCS receives instructions from the EMS. Ensure they use compatible communication protocols so the EMS can effectively tell the PCS when and how to operate.

Poor compatibility leads to poor performance or even system failures.

Crucial Due Diligence: BESS PCS Certifications and Supplier Support

This is about safety, reliability, and peace of mind.

- Certifications: For the US market, look for PCS units with relevant certifications like UL standards (e.g., UL 1741 for inverters) and IEEE standards (e.g., IEEE 1547 for grid interconnection). These show the equipment meets important safety and performance requirements.

- Supplier Support: Who installs and maintains the PCS? What is the warranty period? How responsive is their technical support if something goes wrong? A strong, local supplier network is vital for C&I systems.

Don’t overlook these points. They protect your investment long-term.

Understanding the Players: PCS vs. Other BESS Components

Sometimes terms get mixed up. Let’s quickly clarify the PCS role compared to others.

Is a BESS PCS Just Another Inverter?

Not exactly. While a PCS contains inverter technology (to convert DC to AC), it’s more than just a one-way street.

- Traditional inverters (like for old solar systems) only change DC to AC.

- A BESS PCS is bidirectional. It changes DC to AC ja AC to DC.

- A BESS PCS also includes sophisticated controls specific to managing battery charging and discharging, grid interaction, and operating modes that a standard inverter might not have.

So, while it uses inverter tech, “PCS” is a more accurate and complete term for the power brain of a BESS.

PCS, BMS, and EMS: What’s the Difference in Your BESS?

Think of these as the three main control systems in a BESS:

- BMS (Battery Management System): Focuses vain on the health and safety of the battery itself. It monitors cell voltage, temperature, current, balances cells, and protects against over-charging/discharging. (Protects the muscle)

- PCS (Power Conversion System): Handles the actual flow and conversion of power into and out of the battery. (Manages the power flow)

- EMS (Energy Management System): The highest level control. It decides the strategy based on economics, grid signals, facility needs, etc., and tells the PCS (and sometimes BMS) what to do. (Sets the game plan)

They are all essential and must communicate effectively for the BESS to work correctly.

Päätelmä

The Power Conversion System (PCS) is far more than just a simple converter in your C&I energy storage systems. It’s the vital link that enables your battery to provide real value – from cutting peak demand and saving on bills to keeping your operations running during grid outages.

Understanding the different types of PCS, evaluating their efficiency and features, and ensuring compatibility and proper certifications are critical steps. Don’t let the technical details scare you off. Focus on how the PCS helps the järjestelmä meet your business needs.

Choosing a BESS with the right PCS is a key part of making a smart, reliable energy investment for your future.

Ready to Explore How a C&I BESS, Powered by the Right PCS, Can Benefit Your Business?

Don’t leave money on the table or risk downtime. A properly designed C&I BESS can provide significant savings and peace of mind.

Contact our Kamada power C&I battery energy storage systems manufacturers experts today for a personalized consultation. We’ll help you understand the right BESS configuration, including the ideal PCS, to meet your facility’s specific energy goals.

FAQ

What does PCS stand for in the context of C&I BESS?

Vastaa: PCS stands for Power Conversion System. It’s the equipment that changes electric power between the DC form used by the battery and the AC form used by buildings and the grid.

How does PCS efficiency impact my operational costs?

Vastaa: PCS efficiency is crucial. Every time energy is converted (charged or discharged), a small amount is lost. Higher PCS efficiency means less energy is wasted during these conversions, resulting in more usable energy from your BESS and lower overall electricity bills.

Can I upgrade the PCS in my existing BESS?

Vastaa: It might be possible, but it depends heavily on the design of your current BESS. Upgrading the PCS could potentially improve efficiency or add features like islanding capability, but it requires careful assessment to ensure compatibility with the existing battery and control systems. Always consult with a qualified BESS technician or the original supplier.

Is the PCS included with the battery when purchasing a BESS?

Vastaa: Typically, yes, for C&I applications. The PCS is usually sold as an integrated component within a complete BESS solution, which includes the battery, BMS, PCS, and often the EMS/controls. You don’t usually buy the battery and PCS separately, but always confirm the exact system components included with your supplier.

What are the key safety standards for BESS PCS in the US?

Vastaa: For the US market, important standards often include IEEE 1547 for interconnection with the grid and UL standards (like UL 1741) for safety certification of inverters and converters. Ensure the PCS in your BESS is listed to these relevant standards.

How does PCS cooling affect its lifespan?

Vastaa: Proper cooling is essential for the lifespan and reliability of the PCS’s electronic components. Both air and liquid cooling methods aim to keep the PCS operating within safe temperature ranges. Effective cooling minimizes heat stress, which can prolong the equipment’s life and prevent performance issues or failures. Different cooling methods have different maintenance needs and effectiveness in various climates.