Introduction

Kamada Power is a leading Commercial Energy Storage Systems Manufacturers and Commercial Energy Storage Companies. In commercial energy storage systems, the selection and design of core components directly determine the system’s performance, reliability, and economic viability. These critical components are essential for ensuring energy security, improving energy efficiency, and reducing energy costs. From the energy storage capacity of battery packs to the environmental control of HVAC systems, and from the safety of protection and circuit breakers to the intelligent management of monitoring and communication systems, each component plays an indispensable role in ensuring the efficient operation of energy storage systems.

this article, we will delve into the core components of commercial energy storage systems and commercial battery storage systems, their functions, and applications. Through detailed analysis and practical case studies, we aim to help readers fully understand how these key technologies function in different scenarios and how to choose the most suitable energy storage solution for their needs. Whether addressing challenges related to energy supply instability or optimizing energy utilization efficiency, this article will provide practical guidance and in-depth professional knowledge.

1. PCS (Power Conversion System)

The Power Conversion System (PCS) is one of the core components of commercial energy storage systems, responsible for controlling the charging and discharging processes of battery packs, as well as converting between AC and DC electricity. It mainly consists of power modules, control modules, protection modules, and monitoring modules.

Functions and Roles

- AC/DC Conversion

- Function: Converts DC electricity stored in batteries into AC electricity for loads; can also convert AC electricity into DC electricity to charge batteries.

- Example: In a factory, DC electricity generated by photovoltaic systems during the day can be converted into AC electricity via PCS and directly supplied to the factory. At night or when there is no sunlight, PCS can convert AC electricity obtained from the grid into DC electricity to charge energy storage batteries.

- Power Balancing

- Function: By adjusting output power, it smooths power fluctuations in the grid to maintain power system stability.

- Example: In a commercial building, when there is a sudden increase in power demand, PCS can quickly release energy from batteries to balance power loads and prevent grid overload.

- Protection Function

- Function: Real-time monitoring of battery pack parameters such as voltage, current, and temperature to prevent overcharging, over-discharging, and overheating, ensuring safe system operation.

- Example: In a data center, PCS can detect high battery temperatures and adjust charge and discharge rates immediately to prevent battery damage and fire hazards.

- Integrated Charging and Discharging

- Function: Combined with BMS systems, it selects charging and discharging strategies based on energy storage element characteristics (e.g., constant current charging/discharging, constant power charging/discharging, automatic charging/discharging).

- Grid-Tied and Off-Grid Operation

- Function: Grid-Tied Operation: Provides reactive power automatic or regulated compensation features, low voltage crossing function. Off-Grid Operation: Independent power supply, voltage, and frequency can be adjusted for machine parallel combination power supply, automatic power distribution between multiple machines.

- Communication Function

- Function: Equipped with Ethernet, CAN, and RS485 interfaces, compatible with open communication protocols, facilitating information exchange with BMS and other systems.

Application Scenarios

- Photovoltaic Energy Storage Systems: During the day, solar panels generate electricity, which is converted into AC electricity by PCS for home or commercial use, with surplus electricity stored in batteries and converted back into AC electricity for use at night.

- Grid Frequency Regulation: During fluctuations in grid frequency, PCS provides or absorbs electricity rapidly to stabilize grid frequency. For example, when grid frequency decreases, PCS can discharge quickly to supplement grid energy and maintain frequency stability.

- Emergency Backup Power: During grid outages, PCS releases stored energy to ensure the continuous operation of critical equipment. For example, in hospitals or data centers, PCS provides uninterrupted power support, ensuring uninterrupted operation of equipment.

Technical Specifications

- Conversion Efficiency: PCS conversion efficiency is usually above 95%. Higher efficiency means less energy loss.

- Power Rating: Depending on the application scenario, PCS power ratings range from several kilowatts to several megawatts. For example, small residential energy storage systems may use 5kW PCS, while large commercial and industrial systems may require PCS above 1MW.

- Response Time: The shorter the response time of PCS, the quicker it can respond to fluctuating power demands. Typically, PCS response times are in milliseconds, allowing rapid response to changes in power loads.

2. BMS (Battery Management System)

The Battery Management System (BMS) is an electronic device used to monitor and manage battery packs, ensuring their safety and performance by real-time monitoring and control of voltage, current, temperature, and state parameters.

Functions and Roles

- Monitoring Function

- Function: Real-time monitoring of battery pack parameters such as voltage, current, and temperature to prevent overcharging, over-discharging, overheating, and short circuits.

- Example: In an electric vehicle, BMS can detect abnormal temperatures in a battery cell and adjust charge and discharge strategies promptly to prevent battery overheating and fire hazards.

- Protection Function

- Function: When abnormal conditions are detected, BMS can cut off circuits to prevent battery damage or safety accidents.

- Example: In a home energy storage system, when the battery voltage is too high, BMS immediately stops charging to protect the battery from overcharging.

- Balancing Function

- Function: Balances charge and discharge of individual batteries within the battery pack to avoid large voltage differences between individual batteries, thereby extending the life and efficiency of the battery pack.

- Example: In a large-scale energy storage station, BMS ensures optimal conditions for each battery cell through balanced charging, improving the overall life and efficiency of the battery pack.

- State of Charge (SOC) Calculation

- Function: Accurately estimates the remaining charge (SOC) of the battery, providing real-time status information of the battery for users and system management.

- Example: In a smart home system, users can check the remaining battery capacity through a mobile application and plan their electricity usage accordingly.

Application Scenarios

- Electric Vehicles: BMS monitors the battery status in real-time, prevents overcharging and over-discharging, improves battery lifespan, and ensures the safety and reliability of vehicles.

- Home Energy Storage Systems: Through BMS monitoring, it ensures the safe operation of energy storage batteries and improves the safety and stability of home electricity use.

- Industrial Energy Storage: BMS monitors multiple battery packs in large-scale energy storage systems to ensure efficient and safe operation. For example, in a factory, BMS can detect performance degradation in a battery pack and promptly alert maintenance personnel for inspection and replacement.

Technical Specifications

- Accuracy: The monitoring and control accuracy of BMS directly affects battery performance and lifespan, typically requiring voltage accuracy within ±0.01V and current accuracy within ±1%.

- Response Time: BMS needs to respond rapidly, usually in milliseconds, to handle battery abnormalities promptly.

- Reliability: As the core management unit of energy storage systems, BMS reliability is crucial, requiring stable operation in various working environments. For example, even in extreme temperature or high humidity conditions, BMS ensures stable operation, guaranteeing the safety and stability of the battery system.

3. EMS (Energy Management System)

The Energy Management System (EMS) is the “brain” of commercial energy storage systems, responsible for overall control and optimization, ensuring efficient and stable system operation. EMS coordinates the operation of various subsystems through data collection, analysis, and decision-making to optimize energy utilization.

Functions and Roles

- Control Strategy

- Function: EMS formulates and implements control strategies for energy storage systems, including charge and discharge management, energy dispatching, and power optimization.

- Example: In a smart grid, EMS optimizes the charge and discharge schedules of energy storage systems based on grid load requirements and electricity price fluctuations, reducing electricity costs.

- Status Monitoring

- Function: Real-time monitoring of the operational status of energy storage systems, collecting data on batteries, PCS, and other subsystems for analysis and diagnosis.

- Example: In a microgrid system, EMS monitors the operational status of all energy equipment, promptly detecting faults for maintenance and adjustments.

- Fault Management

- Function: Detects faults and abnormal conditions during system operation, taking protective measures promptly to ensure system safety and reliability.

- Example: In a large-scale energy storage project, when EMS detects a fault in a PCS, it can immediately switch to a backup PCS to ensure continuous system operation.

- Optimization and Scheduling

- Function: Optimizes charge and discharge schedules of energy storage systems based on load requirements, energy prices, and environmental factors, improving system economic efficiency and benefits.

- Example: In a commercial park, EMS intelligently schedules energy storage systems based on electricity price fluctuations and energy demand, reducing electricity costs and improving energy utilization efficiency.

Application Scenarios

- Smart Grid: EMS coordinates energy storage systems, renewable energy sources, and loads within the grid, optimizing energy utilization efficiency and grid stability.

- Microgrids: In microgrid systems, EMS coordinates various energy sources and loads, improving system reliability and stability.

- Industrial Parks: EMS optimizes the operation of energy storage systems, reducing energy costs and improving energy utilization efficiency.

Technical Specifications

- Processing Capability: EMS must have strong data processing and analysis capabilities, able to handle large-scale data processing and real-time analysis.

- Communication Interface: EMS needs to support various communication interfaces and protocols, enabling data exchange with other systems and equipment.

- Reliability: As the core management unit of energy storage systems, EMS reliability is crucial, requiring stable operation in various working environments.

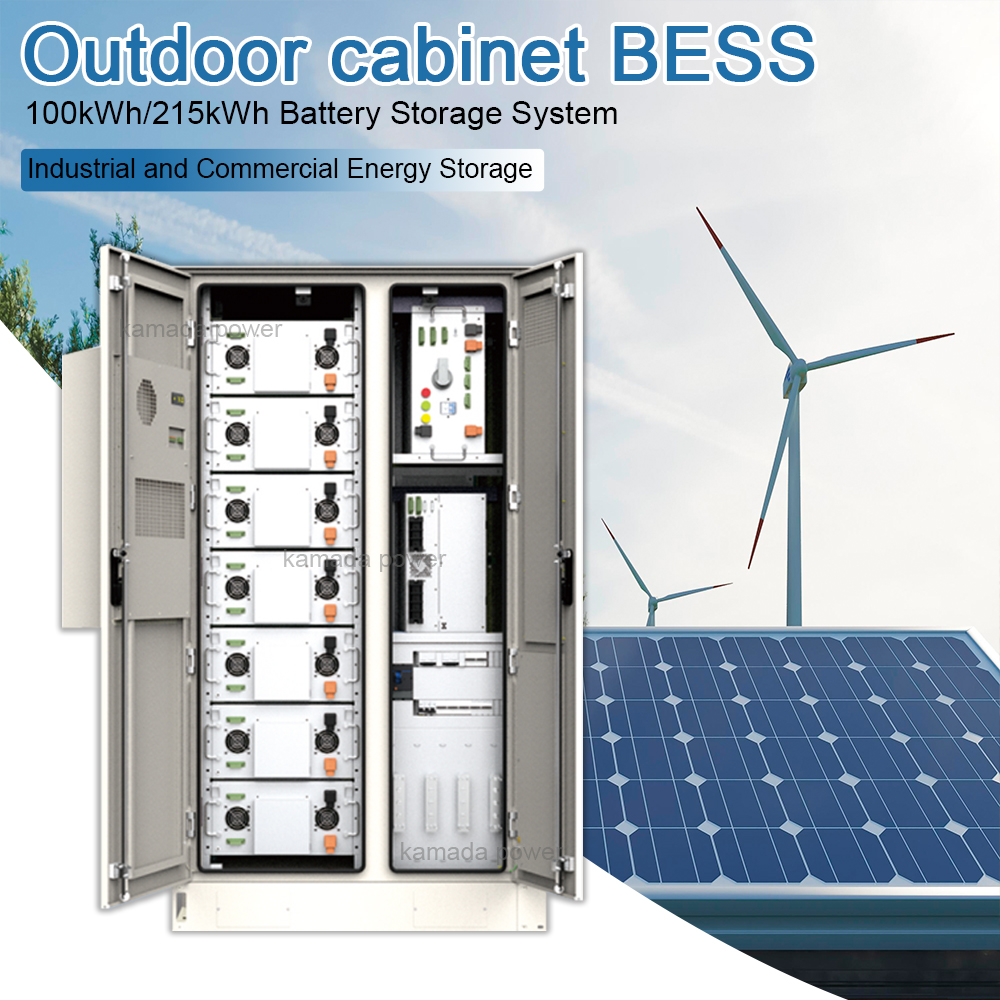

4. Battery Pack

The battery pack is the core energy storage device in commercial battery storage systems, composed of multiple battery cells responsible for storing electrical energy. The selection and design of the battery pack directly impact the system’s capacity, lifespan, and performance. Common commercial and industrial energy storage systems capacities are 100kwh battery and 200kwh battery.

Functions and Roles

- Energy Storage

- Function: Stores energy during off-peak periods for use during peak periods, providing stable and reliable energy supply.

- Example: In a commercial building, the battery pack stores electricity during off-peak hours and supplies it during peak hours, reducing electricity costs.

- Power Supply

- Function: Provides power supply during grid outages or power shortages, ensuring the continuous operation of critical equipment.

- Example: In a data center, the battery pack provides emergency power supply during grid outages, ensuring uninterrupted operation of critical equipment.

- Load Balancing

- Function: Balances power loads by releasing energy during peak demand and absorbing energy during low demand, improving grid stability.

- Example: In a smart grid, the battery pack releases energy during peak demand to balance power loads and maintain grid stability.

- Backup Power

- Function: Provides backup power during emergencies, ensuring the continuous operation of critical equipment.

- Example: In hospitals or data centers, the battery pack provides backup power during grid outages, ensuring uninterrupted operation of critical equipment.

Application Scenarios

- Home Energy Storage: Battery packs store energy generated by solar panels during the day for use at night, reducing reliance on the grid and saving on electricity bills.

- Commercial Buildings: Battery packs store energy during off-peak periods for use during peak periods, reducing electricity costs and improving energy efficiency.

- Industrial Energy Storage: Large-scale battery packs store energy during off-peak periods for use during peak periods, providing stable and reliable energy supply and improving grid stability.

Technical Specifications

- Energy Density: Higher energy density means more energy storage capacity in a smaller volume. For example, high energy density lithium-ion batteries can provide longer usage times and higher power output.

- Cycle Life: The cycle life of battery packs is crucial for energy storage systems. Longer cycle life means more stable and reliable energy supply over time. For example, high-quality lithium-ion batteries typically have a cycle life of over 2000 cycles, ensuring long-term stable energy supply.

- Safety: Battery packs need to ensure safety and reliability, requiring high-quality materials and strict manufacturing processes. For example, battery packs with safety protection measures such as overcharge and over-discharge protection, temperature control, and fire prevention ensure safe and reliable operation.

5. HVAC System

The HVAC System (Heating, Ventilation, and Air Conditioning) is essential for maintaining the optimal operating environment for energy storage systems. It ensures the temperature, humidity, and air quality within the system are maintained at optimal levels, ensuring the efficient and reliable operation of energy storage systems.

Functions and Roles

- Temperature Control

- Function: Maintains the temperature of energy storage systems within optimal operating ranges, preventing overheating or overcooling.

- Example: In a large-scale energy storage station, the HVAC system maintains the temperature of battery packs within the optimal range, preventing performance degradation due to extreme temperatures.

- Humidity Control

- Function: Controls the humidity within energy storage systems to prevent condensation and corrosion.

- Example: In a coastal energy storage station, the HVAC system controls humidity levels, preventing corrosion of battery packs and electronic components.

- Air Quality Control

- Function: Maintains clean air within energy storage systems, preventing dust and contaminants from affecting the performance of components.

- Example: In a desert energy storage station, the HVAC system maintains clean air within the system, preventing dust from affecting the performance of battery packs and electronic components.

- Ventilation

- Function: Ensures proper ventilation within energy storage systems, removing heat and preventing overheating.

- Example: In a confined energy storage station, the HVAC system ensures proper ventilation, removing heat generated by battery packs and preventing overheating.

Application Scenarios

- Large-Scale Energy Storage Stations: HVAC systems maintain the optimal operating environment for battery packs and other components, ensuring efficient and reliable operation.

- Coastal Energy Storage Stations: HVAC systems control humidity levels, preventing corrosion of battery packs and electronic components.

- Desert Energy Storage Stations: HVAC systems maintain clean air and proper ventilation, preventing dust and overheating.

Technical Specifications

- Temperature Range: HVAC systems need to maintain the temperature within the optimal range for energy storage systems, typically between 20°C and 30°C.

- Humidity Range: HVAC systems need to control humidity levels within the optimal range for energy storage systems, typically between 30% and 70% relative humidity.

- Air Quality: HVAC systems need to maintain clean air within energy storage systems, preventing dust and contaminants from affecting the performance of components.

- Ventilation Rate: HVAC systems need to ensure proper ventilation within energy storage systems, removing heat and preventing overheating.

6. Protection and Circuit Breakers

Protection and circuit breakers are crucial for ensuring the safety and reliability of energy storage systems. They provide protection against overcurrent, short circuits, and other electrical faults, preventing damage to components and ensuring the safe operation of energy storage systems.

Functions and Roles

- Overcurrent Protection

- Function: Protects energy storage systems from damage due to excessive current, preventing overheating and fire hazards.

- Example: In a commercial energy storage system, overcurrent protection devices prevent damage to battery packs and other components due to excessive current.

- Short Circuit Protection

- Function: Protects energy storage systems from damage due to short circuits, preventing fire hazards and ensuring the safe operation of components.

- Example: In a home energy storage system, short circuit protection devices prevent damage to battery packs and other components due to short circuits.

- Surge Protection

- Function: Protects energy storage systems from damage due to voltage surges, preventing damage to components and ensuring the safe operation of systems.

- Example: In an industrial energy storage system, surge protection devices prevent damage to battery packs and other components due to voltage surges.

- Ground Fault Protection

- Function: Protects energy storage systems from damage due to ground faults, preventing fire hazards and ensuring the safe operation of components.

- Example: In a large-scale energy storage system, ground fault protection devices prevent damage to battery packs and other components due to ground faults.

Application Scenarios

- Home Energy Storage: Protection and circuit breakers ensure the safe operation of home energy storage systems, preventing damage to battery packs and other components due to electrical faults.

- Commercial Buildings: Protection and circuit breakers ensure the safe operation of commercial energy storage systems, preventing damage to battery packs and other components due to electrical faults.

- Industrial Energy Storage: Protection and circuit breakers ensure the safe operation of industrial energy storage systems, preventing damage to battery packs and other components due to electrical faults.

Technical Specifications

- Current Rating: Protection and circuit breakers need to have the appropriate current rating for the energy storage system, ensuring proper protection against overcurrent and short circuits.

- Voltage Rating: Protection and circuit breakers need to have the appropriate voltage rating for the energy storage system, ensuring proper protection against voltage surges and ground faults.

- Response Time: Protection and circuit breakers need to have a fast response time, ensuring prompt protection against electrical faults and preventing damage to components.

- Reliability: Protection and circuit breakers need to be highly reliable, ensuring the safe operation of energy storage systems in various working environments.

7. Monitoring and Communication System

The Monitoring and Communication System is essential for ensuring the efficient and reliable operation of energy storage systems. It provides real-time monitoring of system status, data collection, analysis, and communication, enabling intelligent management and control of energy storage systems.

Functions and Roles

- Real-Time Monitoring

- Function: Provides real-time monitoring of system status, including battery pack parameters, PCS status, and environmental conditions.

- Example: In a large-scale energy storage station, the monitoring system provides real-time data on battery pack parameters, enabling prompt detection of abnormalities and adjustments.

- Data Collection and Analysis

- Function: Collects and analyzes data from energy storage systems, providing valuable insights for system optimization and maintenance.

- Example: In a smart grid, the monitoring system collects data on energy usage patterns, enabling intelligent management and optimization of energy storage systems.

- Communication

- Function: Enables communication between energy storage systems and other systems, facilitating data exchange and intelligent management.

- Example: In a microgrid system, the communication system enables data exchange between energy storage systems, renewable energy sources, and loads, optimizing system operation.

- Alarms and Notifications

- Function: Provides alarms and notifications in case of system abnormalities, enabling prompt detection and resolution of issues.

- Example: In a commercial energy storage system, the monitoring system provides alarms and notifications in case of battery pack abnormalities, enabling prompt resolution of issues.

Application Scenarios

- Large-Scale Energy Storage Stations: Monitoring and communication systems provide real-time monitoring, data collection, analysis, and communication, ensuring efficient and reliable operation.

- Smart Grids: Monitoring and communication systems enable intelligent management and optimization of energy storage systems, improving energy utilization efficiency and grid stability.

- Microgrids: Monitoring and communication systems enable data exchange and intelligent management of energy storage systems, improving system reliability and stability.

Technical Specifications

- Data Accuracy: Monitoring and communication systems need to provide accurate data, ensuring reliable monitoring and analysis of system status.

- Communication Interface: The monitoring and communication system uses a variety of communication protocols, such as Modbus and CANbus, to achieve data exchange and integration with different devices.

- Reliability: Monitoring and communication systems need to be highly reliable, ensuring stable operation in various working environments.

- Security: Monitoring and communication systems need to ensure data security, preventing unauthorized access and tampering.

8. Custom Commercial energy storage systems

Kamada Power is C&I Energy Storage Manufacturers and Commercial energy storage companies. Kamada Power is committed to providing customized commercial energy storage solutions to meet your specific commercial and industrial energy storage system business needs.

Our Advantage:

- Personalized Customization: We deeply understand your unique commercial and industrial energy storage system requirements. Through flexible design and engineering capabilities, we customize energy storage systems that meet project requirements, ensuring optimal performance and efficiency.

- Technological Innovation and Leadership: With advanced technology development and industry-leading positions, we continuously drive energy storage technology innovation to provide you with cutting-edge solutions to meet evolving market demands.

- Quality Assurance and Reliability: We strictly adhere to ISO 9001 international standards and quality management systems, ensuring every energy storage system undergoes rigorous testing and validation to deliver outstanding quality and reliability.

- Comprehensive Support and Services: From initial consultation to design, manufacturing, installation, and after-sales service, we offer full support to ensure you receive professional and timely service throughout the project lifecycle.

- Sustainability and Environmental Awareness: We are dedicated to developing environmentally friendly energy solutions, optimizing energy efficiency, and reducing carbon footprints to create sustainable long-term value for you and society.

Through these advantages, we not only meet your practical needs but also provide innovative, reliable, and cost-effective custom commercial and industrial energy storage system solutions to help you succeed in the competitive market.

Click Contact Kamada Power Get a Commercial energy storage solutions

Conclusion

commercial energy storage systems are complex multi-component systems. In addition to energy storage inverters (PCS), battery management systems (BMS), and energy management systems (EMS), the battery pack, HVAC system, protection and circuit breakers, and monitoring and communication systems are also critical components. These components collaborate to ensure efficient, safe, and stable operation of energy storage systems. By understanding the functions, roles, applications, and technical specifications of these core components, you can better grasp the composition and operational principles of commercial energy storage systems, providing essential insights for design, selection, and application.

Recommended Related blogs

- What is a BESS System?

- What is OEM Battery Vs ODM Battery?

- Commercial Energy Storage Systems Guide

- Commercial Energy Storage Systems Application Guide

- Degradation Analysis of Commercial Lithium-Ion Batteries in Long-Term Storage

FAQ

What is a C&I energy storage system?

A C&I energy storage system is specifically designed for use in commercial and industrial settings like factories, office buildings, data centers, schools, and shopping centers. These systems play a crucial role in optimizing energy consumption, cutting costs, providing backup power, and integrating renewable energy sources.

C&I energy storage systems differ from residential systems mainly in their larger capacities, tailored to meet the higher energy demands of commercial and industrial facilities. While battery-based solutions, typically using lithium-ion batteries, are most common due to their high energy density, long cycle life, and efficiency, other technologies such as thermal energy storage, mechanical energy storage, and hydrogen energy storage are also viable options depending on specific energy requirements.

How Does a C&I Energy Storage System Work?

A C&I energy storage system operates similarly to residential setups but on a larger scale to handle the robust energy demands of commercial and industrial environments. These systems charge using electricity from renewable sources like solar panels or wind turbines, or from the grid during off-peak periods. A battery management system (BMS) or charge controller ensures safe and efficient charging.

Electrical energy stored in batteries is converted into chemical energy. An inverter then transforms this stored direct current (DC) energy into alternating current (AC), powering the facility’s equipment and devices. Advanced monitoring and control features allow facility managers to track energy generation, storage, and consumption, optimizing energy use and reducing operational costs. These systems can also interact with the grid, participating in demand response programs, providing grid services, and exporting excess renewable energy.

By managing energy consumption, providing backup power, and integrating renewable energy, C&I energy storage systems enhance energy efficiency, reduce costs, and support sustainability efforts.

Benefits of Commercial and Industrial (C&I) Energy Storage Systems

- Peak Shaving & Load Shifting: Reduces energy bills by utilizing stored energy during peak demand periods. For example, a commercial building can significantly cut electricity costs by using an energy storage system during high-rate periods, balancing peak demands and achieving annual energy savings of thousands of dollars.

- Backup Power: Ensures continuous operations during grid outages, enhancing facility reliability. For instance, a data center equipped with an energy storage system can seamlessly switch to backup power during power interruptions, safeguarding data integrity and operational continuity, thereby reducing potential losses due to power outages.

- Renewable Energy Integration: Maximizes the use of renewable energy sources, meeting sustainability goals. For example, by coupling with solar panels or wind turbines, an energy storage system can store energy generated during sunny days and use it during nighttime or cloudy weather, achieving higher energy self-sufficiency and reducing carbon footprint.

- Grid Support: Participates in demand response programs, improving grid reliability. For instance, an industrial park’s energy storage system can rapidly respond to grid dispatch commands, modulating power output to support grid balancing and stable operation, enhancing grid resilience and flexibility.

- Enhanced Energy Efficiency: Optimizes energy usage, reducing overall consumption. For example, a manufacturing plant can manage equipment energy demands using an energy storage system, minimizing electricity wastage, improving production efficiency, and enhancing energy utilization efficiency.

- Improved Power Quality: Stabilizes voltage, mitigating grid fluctuations. For example, during grid voltage fluctuations or frequent blackouts, an energy storage system can provide stable power output, protecting equipment from voltage variations, prolonging equipment lifespan, and reducing maintenance costs.

These advantages not only enhance energy management efficiency for commercial and industrial facilities but also provide a solid foundation for organizations to save costs, increase reliability, and achieve environmental sustainability goals.

What are the different types of Commercial and Industrial (C&I) energy storage systems?

Commercial and Industrial (C&I) energy storage systems come in various types, each selected based on specific energy requirements, space availability, budget considerations, and performance objectives:

- Battery-Based Systems: These systems utilize advanced battery technologies such as lithium-ion, lead-acid, or flow batteries. Lithium-ion batteries, for instance, can achieve energy densities ranging from 150 to 250 watt-hours per kilogram (Wh/kg), making them highly efficient for energy storage applications with long cycle life spans.

- Thermal Energy Storage: This type of system stores energy in the form of heat or cold. Phase change materials used in thermal energy storage systems can achieve energy storage densities ranging from 150 to 500 megajoules per cubic meter (MJ/m³), offering effective solutions for managing building temperature demands and reducing overall energy consumption.

- Mechanical Energy Storage: Mechanical energy storage systems, such as flywheels or compressed air energy storage (CAES), offer high cycle efficiency and rapid response capabilities. Flywheel systems can achieve round-trip efficiencies of up to 85% and store energy densities ranging from 50 to 130 kilojoules per kilogram (kJ/kg), making them suitable for applications requiring instantaneous power delivery and grid stabilization.

- Hydrogen Energy Storage: Hydrogen energy storage systems convert electrical energy into hydrogen through electrolysis, achieving energy densities of approximately 33 to 143 megajoules per kilogram (MJ/kg). This technology provides long-duration storage capabilities and is used in applications where large-scale energy storage and high energy density are crucial.

- Supercapacitors: Supercapacitors, also known as ultracapacitors, offer rapid charge and discharge cycles for high-power applications. They can achieve energy densities ranging from 3 to 10 watt-hours per kilogram (Wh/kg) and provide efficient energy storage solutions for applications requiring frequent charge-discharge cycles without significant degradation.

Each type of C&I energy storage system offers unique advantages and capabilities, allowing businesses and industries to tailor their energy storage solutions to meet specific operational needs, optimize energy use, and achieve sustainability goals effectively.