Custom Battery Suppliers for Industrial Devices. In the industrial world, power is vital, but finding the right battery solution can be daunting. At Kamada Power, we excel at decoding industrial needs, crafting bespoke battery solutions for peak performance. From forklifts to AGVs, we tackle challenges like inconsistent power and short lifespans, ensuring seamless operations. Let us empower your industrial journey with custom batteries designed for efficiency and productivity.

1. Battery Requirements for Industrial Devices

At Kamada Power, our expertise lies in our ability to deeply understand the intricate requirements of various industrial devices. We specialize in providing custom battery solutions for a wide array of equipment, ranging from forklifts and automated guided vehicles (AGVs) to power tools, backup power systems, and robotics, among others.

1.1 Industrial Device Battery Applications

Forklifts Battery

Understanding the demanding nature of forklift operations, we design batteries that can withstand rigorous usage, including frequent charging and discharging cycles. Our batteries are engineered for durability, ensuring prolonged performance in challenging industrial environments.

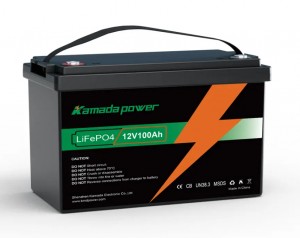

custom industrial devices battery 12v 100ah battery

Automated Guided Vehicles (AGVs) Battery

AGVs operate autonomously in dynamic environments, requiring batteries with exceptional reliability and longevity. We specialize in developing high-energy-density batteries that can power AGVs efficiently, contributing to seamless operations and increased productivity.

custom industrial devices battery agv battery

Power Tools Battery

Power tools demand batteries that can deliver consistent power output and endure constant use. Our customized battery solutions are designed to meet the high power demands of industrial-grade tools, enabling reliable performance in demanding applications such as construction, manufacturing, and maintenance.

Backup Power Systems Battery

Backup power systems are critical for ensuring uninterrupted operations in the event of mains power failure. Our batteries are engineered to provide reliable backup power, with features such as fast charging capabilities and long cycle life, guaranteeing continuous operation during emergencies.

Robotics Battery

Robotics applications often require batteries with precise voltage and capacity specifications to power sophisticated robotic systems. We specialize in developing custom battery packs tailored to the unique power requirements of robotic applications, ensuring optimal performance and efficiency.

1.2 Customized Batteries for Industrial Devices

Durability

Our in-depth understanding of industrial device needs allows us to prioritize durability in battery design. We employ robust materials and advanced manufacturing techniques to create batteries that can withstand the rigors of industrial environments, including exposure to vibration, shock, and extreme temperatures.

Performance in Harsh Environments

Industrial environments can be harsh, with factors such as dust, moisture, and temperature fluctuations posing challenges to battery performance. Our batteries are designed to excel in these conditions, with features such as ruggedized casings, sealed enclosures, and temperature management systems to ensure reliable operation.

High Energy Density

Industrial devices often require batteries with high energy density to power demanding applications while maintaining compact size and weight. Leveraging our expertise in battery chemistry and design optimization, we deliver solutions that maximize energy density without compromising on performance or reliability.

Safety and Compliance

Safety is paramount in industrial settings, and our batteries are engineered to meet the highest safety standards and regulatory requirements. We adhere to industry certifications such as ISO 9001 and ISO 14001, ensuring that our products are manufactured and tested to stringent quality and safety standards.

Customizable Solutions

We understand that one size does not fit all when it comes to industrial batteries. That’s why we offer customizable solutions tailored to the specific needs of each application. Whether it’s adjusting voltage and capacity specifications or designing custom form factors to fit unique device configurations, we work closely with our clients to deliver tailored solutions that meet their exact requirements.

our comprehensive understanding of industrial device needs, combined with our expertise in battery design and engineering, allows us to deliver customized solutions that excel in durability, performance, safety, and compliance. With Kamada Power, you can trust that your industrial devices will be powered by batteries specifically engineered to meet their unique requirements, ensuring reliable operation and maximum productivity.

2. Industrial Devices Custom Battery Customer Case

Forklifts Battery Custom Case

Background:

John Miller, CEO of a leading logistics solutions provider, specializes in forklift operations across various industries.

Scenario:

John Miller operates in a large warehouse facility where forklifts play a crucial role in moving inventory and materials. However, their current forklift batteries face challenges as they prematurely fail due to the severity of operations.

Pain Points:

- Increased downtime and decreased productivity due to battery issues.

- Battery wear and tear from frequent charging and discharging cycles.

- Unstable forklift performance due to battery issues.

Requirements:

John Miller needs forklift batteries that can withstand rigorous usage and provide stable performance in challenging industrial environments.

Solution:

Kamada Power collaborates with John Miller to design custom forklift batteries to meet his specific requirements. These batteries are built with robust lithium-ion cells known for their high cycle life and durability. Additionally, advanced battery management systems (BMS) are integrated to optimize charging and discharging cycles, reducing wear and tear on the batteries. The battery packs are also equipped with temperature sensors and cooling systems to ensure stable performance even in extreme conditions.

Outcomes:

- Reduced downtime and increased productivity due to 30% fewer battery failures.

- Improved forklift performance and reliability, resulting in a 25% increase in daily throughput.

- Extended battery life by 40%, leading to substantial cost savings on replacements and maintenance.

- Enhanced warehouse worker safety through reliable forklift operations, reducing accidents by 15%.

Automated Guided Vehicles (AGVs) Battery Custom Case

Background:

Emily Roberts, CEO of an automation solutions provider, specializes in AGV systems for warehouses and manufacturing facilities.

Scenario:

Emily Roberts is developing a new AGV system for a client’s warehouse operations. They require high-performance batteries to power AGVs effectively and reliably in dynamic environments.

Pain Points:

- Limited battery options currently available that meet the specific requirements of AGV systems.

- Concerns about battery reliability and lifespan in autonomous operation scenarios.

- Need for batteries with high energy density to optimize AGV performance and runtime.

Requirements:

Emily Roberts needs AGV batteries with exceptional reliability, lifespan, and high energy density to ensure seamless operations and increased productivity in dynamic environments.

Solution:

Kamada Power partners with Emily Roberts to design AGV batteries tailored to her client’s needs. These batteries utilize cutting-edge lithium-polymer technology, offering superior energy density and extended cycle life. To address concerns about reliability, redundant BMS systems are incorporated to ensure continuous operation even in the event of a single component failure. Additionally, rapid-charging capabilities are integrated to minimize downtime during battery swaps, optimizing AGV uptime.

Outcomes:

- Enhanced reliability and lifespan of AGV batteries, minimizing downtime and increasing productivity by 20%.

- Improved AGV performance and runtime in dynamic warehouse environments, leading to a 30% increase in order fulfillment speed.

- Cost savings on battery replacements and maintenance due to extended lifespan, amounting to $100,000 annually.

- Increased efficiency and productivity in warehouse operations with reliable AGV performance, resulting in a 15% reduction in labor costs.

Power Tools Battery Custom Case

Background:

Michael Johnson, CEO of a construction equipment manufacturing company in Los Angeles, specializes in producing high-quality power tools for construction and manufacturing industries.

Scenario:

Michael Johnson’s company, based in Chicago, manufactures power tools used in construction sites and manufacturing plants. However, they face challenges with their current batteries, which struggle to deliver consistent power output and endure constant use in demanding applications.

Pain Points:

- Inconsistent power output affecting the performance of power tools.

- Short battery lifespan leading to frequent replacements and downtime.

- Limited battery options available in the market that meet the specific power demands of industrial-grade tools.

Requirements:

Michael Johnson needs power tool batteries that can deliver consistent power output, endure constant use, and meet the high power demands of industrial-grade tools.

Solution:

Kamada Power collaborates with Michael Johnson to develop customized power tool batteries tailored to his company’s requirements. These batteries are designed with advanced lithium-ion technology and feature intelligent battery management systems to ensure stable power output in the most demanding environments. Additionally, they are constructed with high-quality materials for exceptional durability and cycle life, minimizing replacement frequency and downtime.

Outcomes:

- Improved performance and reliability of power tools with consistent power output.

- Extended battery lifespan resulting in reduced replacements and downtime.

- Increased efficiency and productivity in construction and manufacturing operations.

- Cost savings on battery replacements and maintenance, contributing to overall profitability.

Backup Power Systems Battery Custom Case

Background:

Jessica Williams, CEO of a data center solutions provider in New York City, specializes in providing reliable backup power systems for data centers and critical facilities.

Scenario:

Jessica Williams’s company operates data centers in Houston that require reliable backup power systems to ensure uninterrupted operations in the event of mains power failure. However, their current backup power systems face challenges with battery reliability and fast charging capabilities.

Pain Points:

- Concerns about battery reliability and lifespan in critical backup power applications.

- Need for batteries with fast charging capabilities to minimize downtime during emergencies.

- Limited options available in the market that meet the specific requirements of data center backup power systems.

Requirements:

Jessica Williams needs backup power system batteries with exceptional reliability, fast charging capabilities, and long cycle life to ensure continuous operation during emergencies.

Solution:

Kamada Power collaborates with Jessica Williams to design custom backup power system batteries tailored to her company’s requirements. These batteries leverage advanced technology to provide reliable backup power and fast charging capabilities. They are engineered for long cycle life and durability to meet the stringent demands of data center backup power applications.

Outcomes:

- Enhanced reliability and performance of backup power systems, ensuring uninterrupted operations during mains power failure.

- Reduced downtime and increased uptime with fast-charging batteries.

- Extended battery lifespan resulting in cost savings on replacements and maintenance.

- Improved reliability and resilience of data center operations, enhancing customer satisfaction and trust.

3. Technical Support and Service:

From pre-sale consultation to after-sales support, we provide comprehensive assistance throughout the integration process. Our dedicated technical support team is committed to ensuring a smooth transition, offering installation assistance, maintenance, troubleshooting, and training resources for your team.

Pre-sale Consultation:

Before embarking on the integration process, our team collaborates with you to thoroughly understand your needs and objectives. Our pre-sale consultation service aims to assist you in identifying the best battery solution to meet your specific requirements. Our professional consultants will analyze your equipment configurations, power requirements, and budget constraints, providing personalized recommendations and solutions.

Installation Assistance:

Once you have identified the optimal battery solution, our technical support team provides comprehensive installation assistance. Our skilled technicians work with your team to ensure the correct installation and configuration of the batteries. We provide detailed installation guides and technical support to ensure everything goes smoothly, minimizing downtime to the fullest extent.

Maintenance and Troubleshooting:

We understand that the smooth operation of equipment is crucial for production and business in industrial environments. Therefore, our technical support team is available to provide maintenance and troubleshooting support at all times. Whether it’s regular maintenance or sudden breakdowns, our professional technicians respond promptly and provide quick and effective solutions to ensure your equipment remains in optimal condition.

Training Resources:

To help your team make the most of our battery solutions, we offer comprehensive training resources. Our training courses cover safe operation, maintenance, and troubleshooting of batteries, aimed at turning your team into battery experts. Our training programs can be customized according to your specific needs and levels, ensuring maximum benefit for your team.

Our unmatched technical support and service are dedicated to providing you with comprehensive support throughout the integration process, from pre-sale consultation to after-sales support, ensuring a smooth transition for your battery integration. Whatever challenges you face, our professional technical team is ready to assist you at any time, ensuring that your equipment remains in optimal condition.

4. Why Choose Kamada Power Customized Batteries for Industrial Devices

At Kamada Power, we provide compelling reasons for you to choose us as your trusted partner for customized battery solutions. Let’s delve into each reason to understand why we stand out in the industry:

4.1 Extensive Experience and Specialized Knowledge

Our wealth of experience in the industrial sector sets us apart. Over the years, we have built strong partnerships with leading manufacturers, consolidating our expertise in custom battery solutions for industrial equipment. We deeply understand the requirements of various industrial devices and develop battery solutions tailored to ensure their prolonged stable operation in demanding work environments.

4.2 Unique Requirements of Industrial Equipment Batteries

Battery requirements in the industrial sector significantly differ from conventional applications. Industrial equipment often operates in harsh conditions such as high temperatures, low temperatures, high humidity, or intense vibrations. Therefore, industrial equipment batteries must possess higher durability and stability to ensure long-term reliable operation. Additionally, industrial equipment typically requires higher energy density and power output to meet the high-power demands of the equipment. We design and customize battery solutions to address these special requirements, ensuring reliable operation under various adverse conditions and providing the necessary energy support.

4.3 Customized Battery Solutions

We understand that a one-size-fits-all approach doesn’t work in battery solutions. Therefore, we take pride in precisely meeting your specifications. Whether it’s voltage, capacity, or size requirements, we work closely with you to ensure seamless integration with your existing device designs. Our customized approach guarantees optimal performance and compatibility, enabling you to run your operations efficiently with confidence.

4.4 Compliance with Regulations and Safety Standards

Safety and compliance are non-negotiable aspects of our business. We strictly adhere to ISO certifications, follow UL, IEC safety standards, and environmental regulations, demonstrating our commitment to quality and sustainability. Our commitment to quality and sustainability is reflected in every battery we produce. You can rest assured that our batteries meet the highest industry standards, providing you with peace of mind and compliance assurance.

4.5 Advanced Quality Assurance and Testing Protocols

Quality is fundamental to everything we do. Our batteries undergo rigorous testing to ensure they meet strict safety, performance, and durability requirements. From initial design to final production, every step is carefully monitored and tested to ensure the reliability of our batteries. With our advanced testing protocols, you can trust that your business is powered by batteries of the highest quality and reliability.

4.6 State-of-the-Art Manufacturing Capabilities

Our manufacturing facilities are equipped with state-of-the-art technology and possess advanced capabilities. We are flexible to scale production to meet your demands while easily accommodating custom orders. Our commitment to innovation and excellence ensures that you receive top-notch battery solutions that exceed your expectations.

Conclusion

Kamada Power not only has extensive experience and expertise in industrial equipment batteries but also provides highly customized solutions to meet various special requirements. Whatever battery solution your industrial equipment needs, we can provide professional support and high-quality service to ensure your equipment remains efficient and stable. click contact us kamada power get a quote