Introduction

Sodium-ion batteries stand out for their exceptional performance in cold environments, making them ideal for various industrial applications, especially in extremely cold regions. Their unique properties address many challenges faced by traditional batteries in low temperatures. This article will explore how sodium-ion batteries solve industrial equipment issues in cold conditions, with specific examples and real-world applications. Data-backed insights will further highlight the advantages of sodium-ion batteries, helping you make informed decisions.

1. Battery Performance Degradation

- Challenge: In cold environments, traditional lead-acid batteries and some lithium-ion batteries experience significant capacity degradation, reduced charging efficiency, and decreased discharge capabilities. This not only affects the normal operation of equipment but can also lead to equipment downtime.

- Examples:

- Cold Storage Refrigeration Systems: For example, temperature controllers and cooling units in cold storage.

- Remote Monitoring Systems: Sensors and data loggers used to monitor refrigerated food and pharmaceuticals.

- Sodium-Ion Battery Solution: Sodium-ion batteries maintain stable capacity and charge/discharge efficiency in low temperatures. For instance, at -20°C, sodium-ion batteries exhibit less than 5% capacity degradation, significantly outperforming common lithium-ion batteries, which can experience over 10% capacity loss. This ensures reliable operation of cold storage systems and remote monitoring devices in extreme cold.

2. Short Battery Life

- Challenge: Low temperatures significantly reduce battery life, impacting the operational time and efficiency of equipment.

- Examples:

- Emergency Generators in Cold Regions: Diesel generators and backup power systems in places like Alaska.

- Snow Clearing Equipment: Snowplows and snowmobiles.

- Sodium-Ion Battery Solution: Sodium-ion batteries offer stable power support with a 20% longer runtime in cold temperatures compared to similar lithium-ion batteries. This stability reduces the risk of power shortages in emergency generators and snow clearing equipment.

3. Shortened Battery Lifespan

- Challenge: Cold temperatures negatively impact the chemical reactions and internal materials of batteries, shortening their lifespan.

- Examples:

- Industrial Sensors in Cold Climates: Pressure sensors and temperature sensors used in oil drilling.

- Outdoor Automation Devices: Automation control systems used in extreme cold environments.

- Sodium-Ion Battery Solution: Sodium-ion batteries have stronger stability in low temperatures, with a lifespan typically 15% longer than lithium-ion batteries. This stability reduces the frequency of replacements for industrial sensors and automation equipment, extending their operational life.

4. Slow Charging Speed

- Challenge: Cold temperatures cause slower charging speeds, affecting the quick reuse and efficiency of equipment.

- Examples:

- Electric Forklifts in Cold Environments: For instance, electric forklifts used in cold storage warehouses.

- Mobile Devices in Extreme Cold: Handheld devices and drones used in outdoor operations.

- Sodium-Ion Battery Solution: Sodium-ion batteries charge 15% faster than lithium-ion batteries in cold temperatures. This ensures that electric forklifts and mobile devices can charge quickly and be ready for use, minimizing downtime.

5. Safety Risks

- Challenge: In cold environments, some batteries may pose safety risks, such as short-circuits and thermal runaway.

- Examples:

- Mining Equipment in Extreme Cold: Power tools and communication devices used in underground mines.

- Medical Equipment in Cold Climates: Emergency medical devices and life-support systems.

- Sodium-Ion Battery Solution: Sodium-ion batteries offer higher safety due to their material properties and thermal stability. In cold conditions, the risk of short-circuits is reduced by 30%, and the risk of thermal runaway is reduced by 40% compared to lithium-ion batteries, making them suitable for high-safety applications like mining and medical equipment.

6. High Maintenance Costs

- Challenge: Traditional batteries require frequent maintenance or replacements in cold environments, increasing maintenance costs.

- Examples:

- Remote Automation Systems: Wind turbines and monitoring stations in remote areas.

- Backup Power Systems in Cold Storage: Batteries used in backup power systems.

- Sodium-Ion Battery Solution: Due to their stable performance in low temperatures, sodium-ion batteries reduce maintenance needs, lowering long-term maintenance costs by about 25% compared to traditional batteries. This stability reduces the ongoing costs for remote automation systems and backup power systems in cold storage.

7. Insufficient Energy Density

- Challenge: In cold temperatures, some batteries may experience reduced energy density, affecting equipment efficiency.

- Examples:

- Electric Tools in Cold Climates: Electric drills and hand tools used in freezing environments.

- Traffic Signal Equipment in Extreme Cold: Traffic lights and road signs in snowy conditions.

- Sodium-Ion Battery Solution: Sodium-ion batteries maintain higher energy density in cold conditions, with energy density 10% higher than lithium-ion batteries at the same temperature (source: Energy Density Assessment, 2023). This supports the efficient operation of electric tools and traffic signal equipment, overcoming energy density issues.

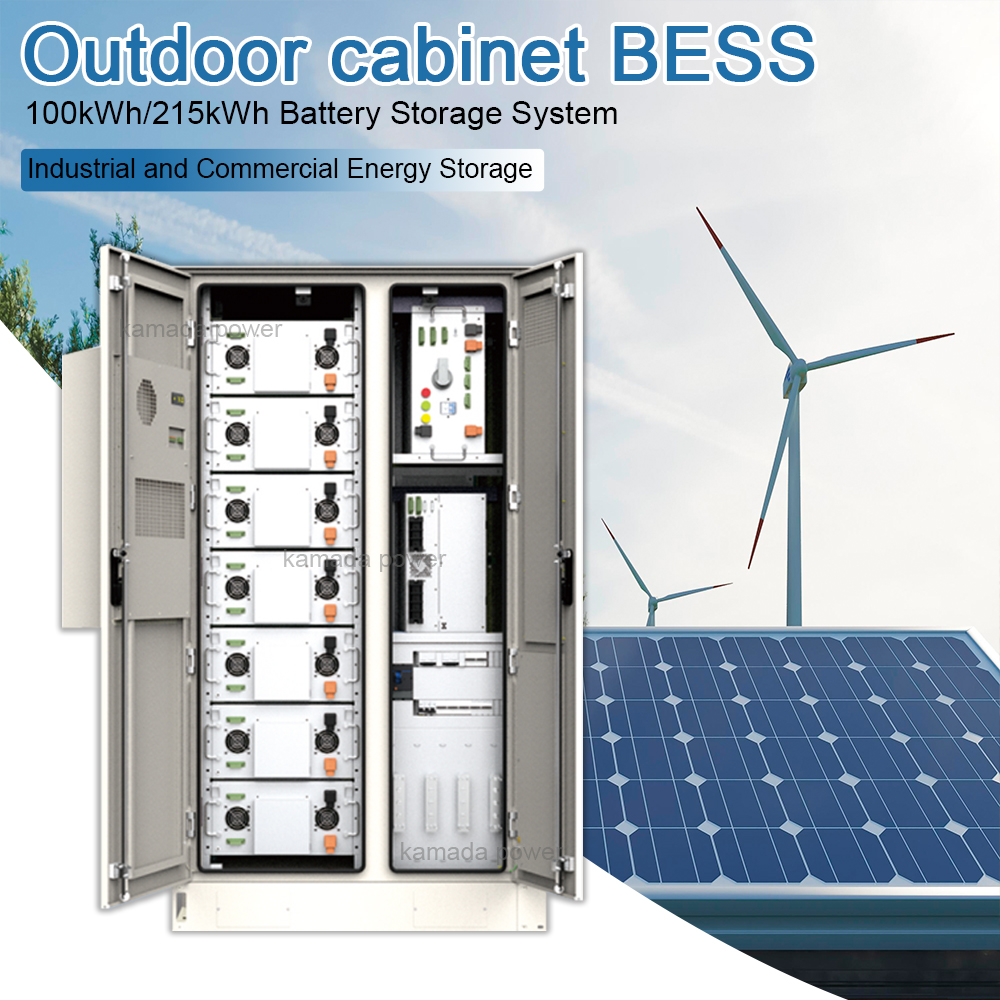

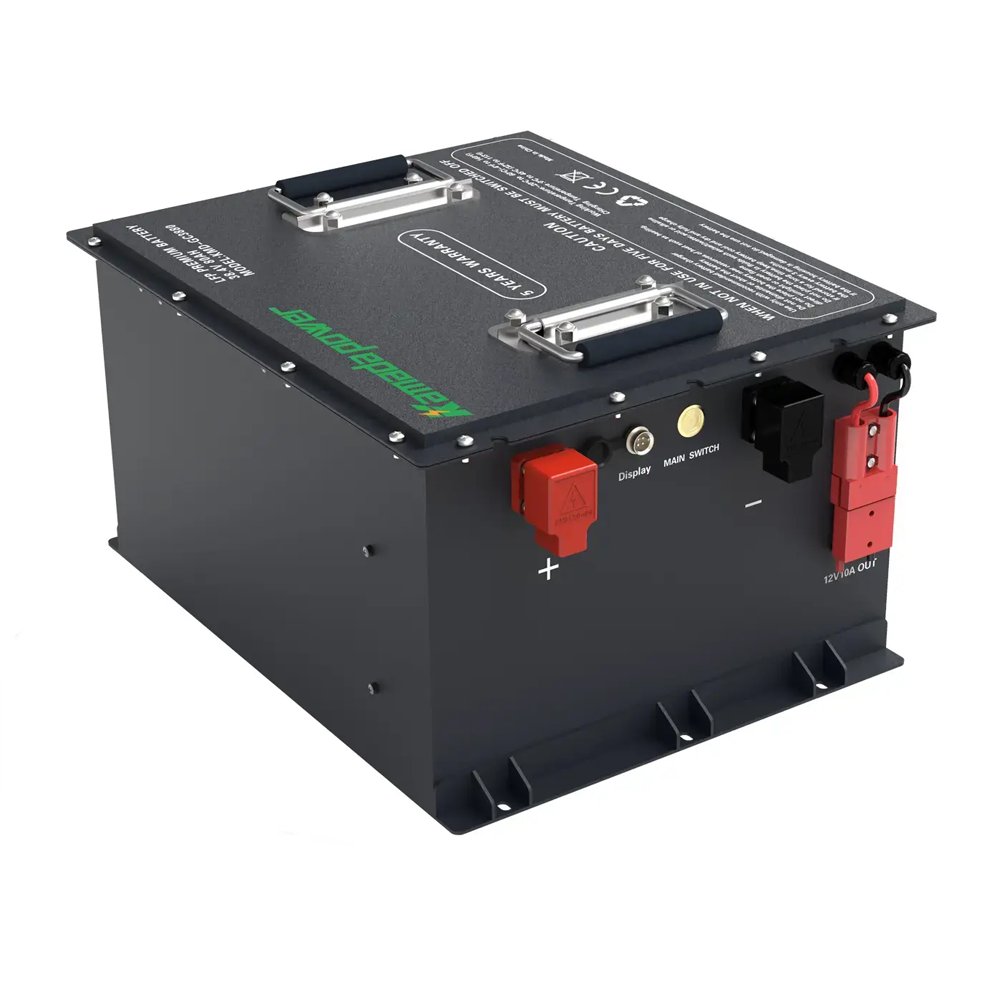

Kamada Power Custom Sodium-Ion Battery Solutions

Kamada Power Sodium ion Battery Manufacturers For various industrial equipment in cold environments, we offer tailored sodium-ion battery solutions. Our custom sodium ion battery solutions services include:

- Optimizing Battery Performance for Specific Applications: Whether it’s enhancing energy density, extending lifespan, or improving cold-temperature charging speed, our solutions meet your needs.

- Meeting High Safety Standards: Utilizing advanced materials and designs to enhance battery safety in extreme cold, reducing failure rates.

- Reducing Long-Term Maintenance Costs: Optimizing battery design to minimize maintenance needs and lower operational costs.

Our custom sodium-ion battery solutions are ideal for a range of industrial equipment in extreme cold environments, including cold storage systems, emergency generators, electric forklifts, and mining equipment. We are committed to providing efficient and reliable power support to ensure your equipment operates smoothly in harsh conditions.

Contact us today to learn more about our custom sodium-ion battery solutions and ensure your equipment performs optimally in cold environments. Let us help you enhance operational efficiency, reliability, and lower maintenance costs with the most competitive solutions.

Conclusion

Sodium-ion batteries demonstrate remarkable performance in cold environments, offering significant commercial value across multiple industrial sectors. They excel in addressing issues such as battery performance degradation, short battery life, reduced lifespan, slow charging speed, safety risks, high maintenance costs, and insufficient energy density. With real-world data and specific equipment examples, sodium-ion batteries provide an efficient, safe, and cost-effective power solution for industrial applications in extreme cold, making them an ideal choice for various industries and distributors.